Part IV Company innovation and development

In the uncertain and unstable economic development, Company is making preparations of all risk control during the peace time, and had made active change and upgrade of their business management models, and promote Company transformation. In 2020, Handa Industries continuese to integrate the sense of innovation in its operations, and use innovation as the driving force for Company growth and development. We have achieved new breakthroughs in product innovation, technological innovation, brand promotion, and sales and management innovation.

Product innovation

□Hanuo sports functional fabrics

Functional fabrics have always been a hot textile product that is widely pursued internationally. It originates from people's pursuit of a green, healthy and comfortable life. The company keeps up with fashion trends, takes sustainable fashion as the focus of research and development, and develops a variety of environmentally friendly sports fabrics. The products developed have won important awards in the industry and have been widely recognized by the industry and the market.

01.Environmental protection series

The global spread of COVID-19 still continues. Under the epidemic, people over the world travel less, and nature's self-repair mode has started. The mode of coexistence between mankind and nature needs to be improved, sustainable development has become the main theme of current world development, and the transformation of the textile industry is imminent. In 2020, company has made great efforts to promote the development of environmental protection, search materials that can replace conventional non-degradable chemical fibers, using recycled and renewable materials SORONA, PLA, and has developed environmentally friendly series of fabrics.

Among them, SORONA series fabrics are widely used in all kinds of clothing, from light underwear to thick outerwear. On the raw material side, SORONA reduces petroleum resource consumption by 37% compared to nylon, saves energy use by 30%, and reduces greenhouse gas emissions by 63%. SORONA's natural spring-like structure makes the fabric elastic and comfortable, stiff and self-cultivating. The grooved structure gives consumers a clean and refreshing experience of perspiration and breathability.

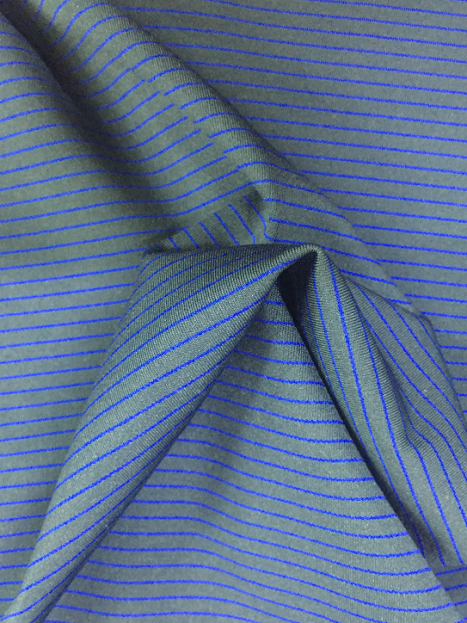

At the same time, the company uses biodegradable PLA corn fiber with a very short regeneration cycle of 1-2 years, and mixes it with low-temperature dyeable polyester fiber in an optimal ratio, and designs environmentally friendly series of knits including linen gray jersey and striped cotton wool cloth. The fabric has excellent natural antibacterial properties and flame retardant effects.

As consumers become more and more adapted to the independent lifestyle in the post-epidemic era, primitive fitness methods such as yoga are favored by more people, and products with linkage and auxiliary functions have become new hot trends. In 2020, following the market trend, the company keeps on optimization and upgrading on the basis of the polyester-spandex high-elastic series, select nylon fiber with excellent elasticity, recovery and abrasion resistance as the main material, and develop various fabrics.

This series of fabrics have high elasticity, tight cloth patterns, good body shaping effect, and freely stretch following exercises, provide consumers with a comfortable, stable and fitting wearing experience.

03. Store heat to keep warm

In order to meet consumers' demands for heat storage, warmth, and lightness in autumn and winter clothing, in 2020, the company continues to work with Jiangnan University R&D team to conduct in-depth research on the heat storage and warmth function, overcome many difficulties,and successfully realize the technology X-thermal,which maximize the use of light energy.

X-thermal technology uses ecological nano-scale heating particles to absorb high-energy waves in sunlight and convert them into heat; at the same time, it absorbs short-wave infrared rays from the human body and continues to heat up to achieve the super heating effect of H-WARM series fabrics. After testing, compared with conventional fabrics, the heating value of thermal storage and thermal insulation fabrics can be steadily increased by 10℃+.

The H-WARM series fabrics subvert the bloated appearance of the previous temperature control jackets, and the low-weight fabrics create a light and elegant appearance. Let people wear it indoors for a long time without burden, flexibly carry out outdoor sports, travel at any time, and

■Technological innovation

In order to strengthen lean production, improve production efficiency and product quality, the company actively encourages all employees to innovate in technology and craftsmanship to promote production process optimization, efficiency improvement and cost reduction.

Technological innovation

In order to meet customer requirements and improve production efficiency, Handa garment factory actively encourages all employees to make innovations in technology and process, and promotes production process optimization, efficiency improvement and cost reduction.

In 2020, all the staff of the Company open their minds to work to improve the process through template technology and gadgetry creation etc. After repeated study and debugging, several processes were optimized on the basis of ensuring product quality, among them three processes improve the production efficiency incredibly.

Automatic template for edge overlock

Before improvement: During the operation, the staff controlled the cut panel by hands, and the stitching distance was not stable, which could not guarantee the shape of the finished product.

After improvement: The stitching goes automatically, no need to hold the template by hand, the stitching distance is even, and the quality is guaranteed. With automatic thread cutting function, there is no need to cut the thread manually after stitching;The two templates are used alternately, and the staff can place the second cutting piece while the machine is running to reduce the waiting time.

Bartack machines to sew small label

Before improvement: To use flat sewing machine to sew small label, skilled workers are required due to the difficulty of radian turn of labels. And it takes 32 seconds for one piece, low efficiency.

After improvement: Fixing label position and setting the bartack machine according to fixed position, then starting automatic sewing, much smoother stitching lines than manual sewing, each piece is completed in 6 seconds in high efficiency. The efficiency was improved 81%.

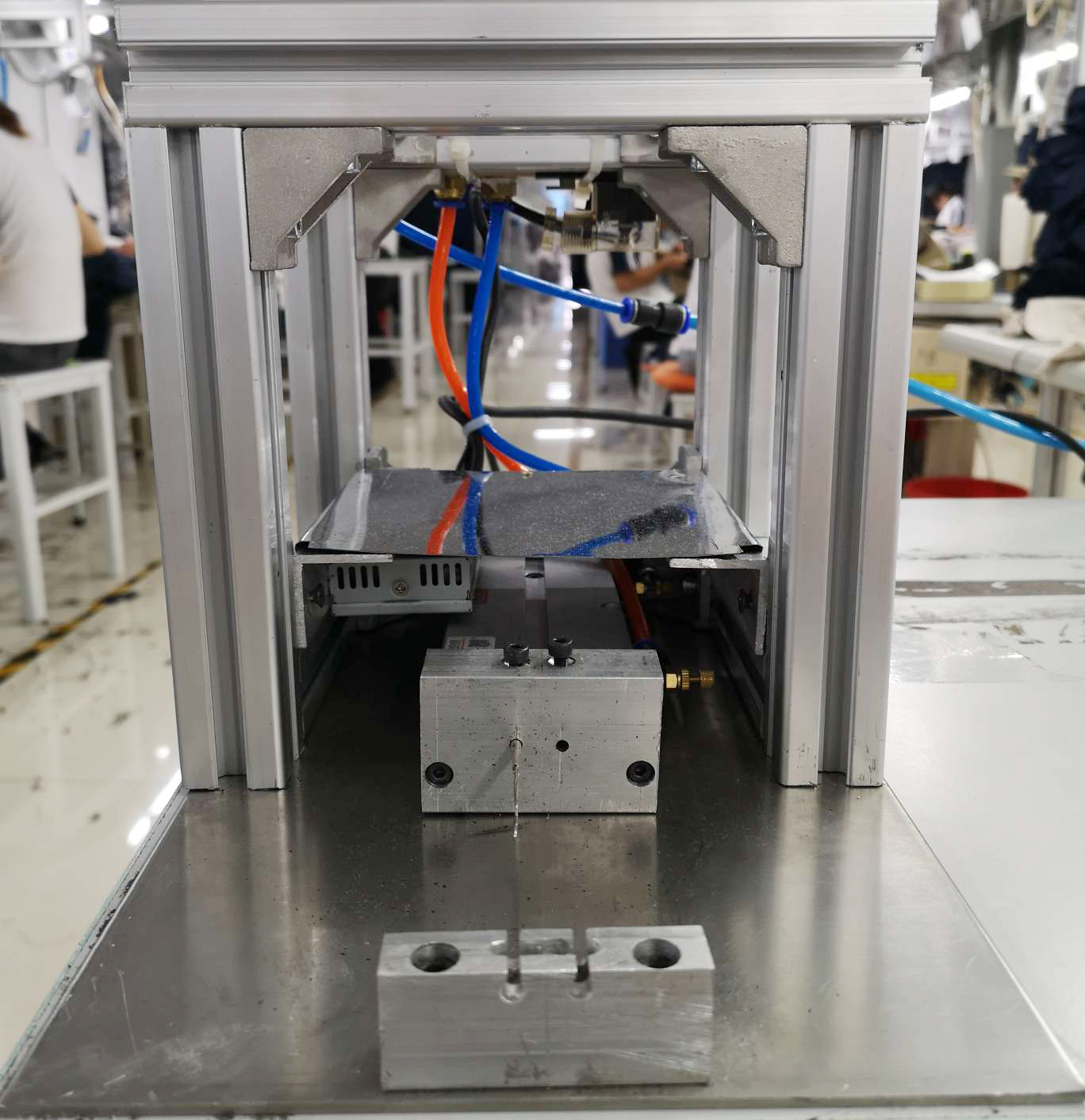

Automatic drawstring going through tool

Before improvement: When putting the drawstring into the small tube, the worker needs to use one hand to hold one side meanwhile another hand to go through down, low efficiency and easy to fatigue and it took 59 seconds to finish one piece.

After improvement:Put the drawstring stopper into the mold, use the cylinder to push it into the small tube, put the drawstring into the slot of the cylinder, and pull the drawstring directly through tube by the cylinder, which improves the operation speed and saves time and effort. Using the cylinder to go through from one side hole to other side takes 34 seconds, the efficiency is 42% higher than before.

Sales innovation

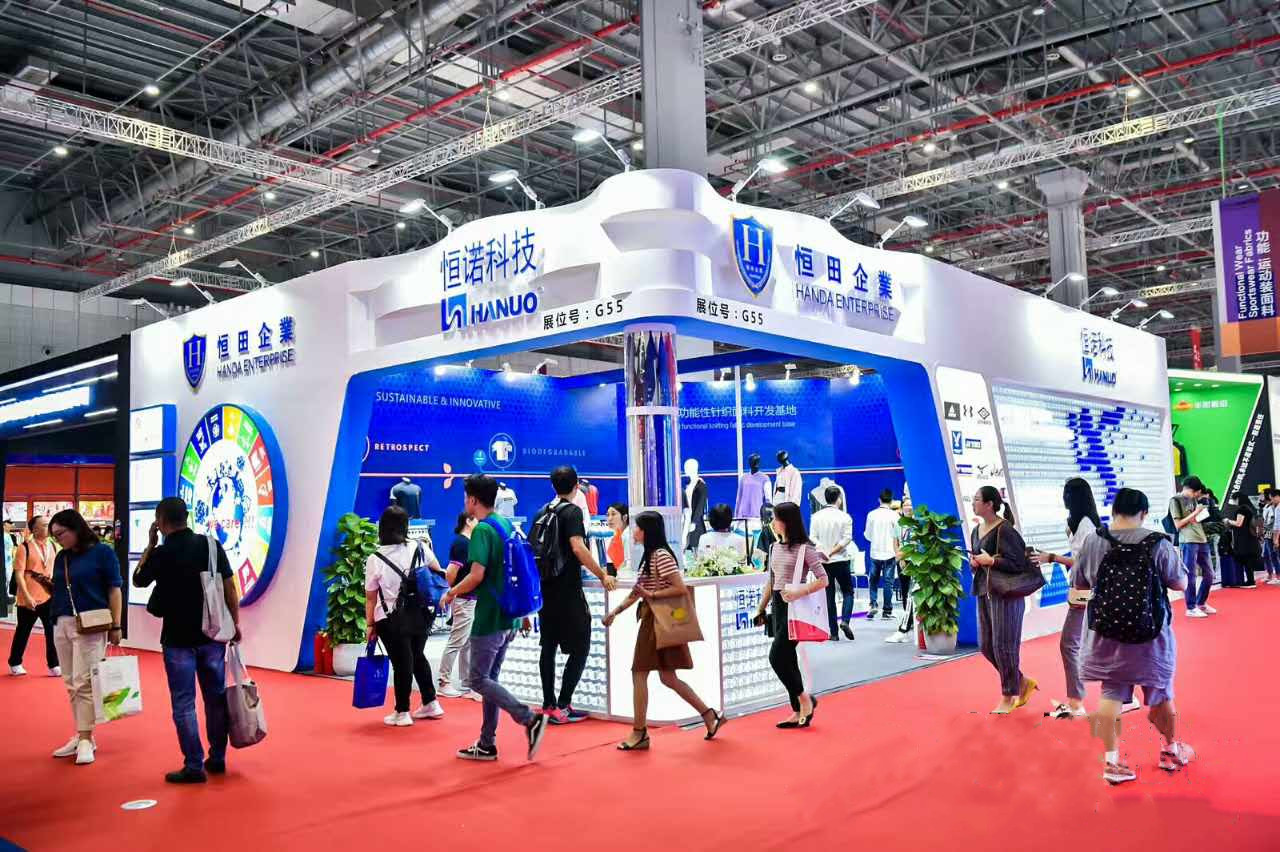

Participate in large international exhibitions to attract many buyers consulting cooperation

In 2019, Handa participated in Germany ISPOExhibition, Shanghai International Textile Expo in spring and Autumn of 2019,US OUTDOOR Exhibition, Ethiopian Garment Industry Exhibition and other largeinternational exhibitions, showing to the outside world the comprehensivestrength of Handa in fiber, yarn, fabric, garment and other aspects. In theexhibitions, we showed our products under the theme "Let's make fashionsustainable & innovative", attracted numerous domestic and foreigncustomers to exchange and cooperate

-b344be2f-503b-4a5a-acbf-68ba2ebe4ff9.jpg)

Service innovation

Handa's thirdoverseas garment factory opened for production

To meet theincreasing demand from customers, Handa Enterprises opened its third garmentfactory, Hanboom (Myanmar) Garments Co., LTD., in Shwe Lin Ban Industrial Zone, Yangon,Myanmar.

Hanboom(Myanmar) covers an area of 16,000 square meters, with 35 assembly lines, canaccommodate more than 1,500 employees.The establishment of the third plant inMyanmar has improved the production capacity of the enterprise and can betterserve customers.

Improve the industrial chain of overseas factories and build vertical supply chain factories with more than 10,000 staffs in Myanmar

In 2019, in addition to the smooth commissioning of no.3 plant in Myanmar, The no.4 plant in Myanmar has entered the stage of recruitment while decorating, and the expansion project of No.2 plant in Myanmar is also progressing steadily.At the same time, the knitting factory and the printing and dyeing factory as supporting facilities of garments factories are also undergoing infrastructure construction and are scheduled to complete and start trial operation around June 2020.

Handa enterprises will take the lead in Myanmar to build up a relatively complete vertical manufacture chain including knit fabric and ready wear garments.It is expected that by the end of 2020, we will reach to 10,000 workers manufacturer in Myanmar with knitting, dying and garmentsproduction.

Handa enterprise opens Egyptian garment base

On November 16, the first phase of cooperation agreement between Handa Enterprise and Egypt Cotton Textile Industry Holding Company was formally signed in The Egyptian Ministry of Industry and Trade, marking the official settlement of Handa enterprise in Africa.Following the signing of the agreement, Handa Enterprises will use the 35,000 square meters of land and plant of Egypt Cotton Textile Holding Company located in Bilbes to open the Egyptian garment base, launching a new development milestone.

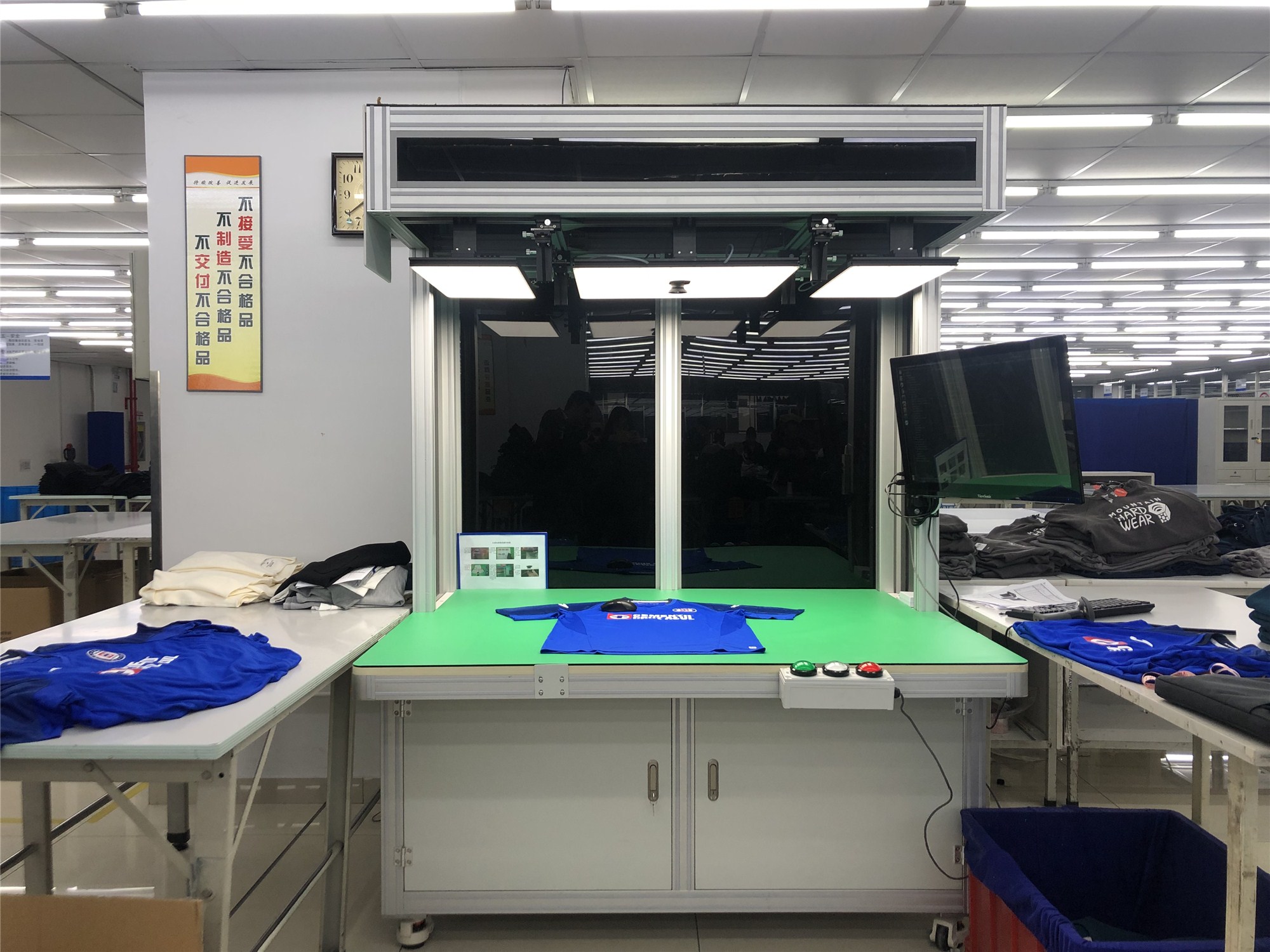

Equipment replacement

Introduced new equipment to upgrade capacity and efficiency

During the year, Handa enterprise introduced a single round machine, cotton dyeing machine, automatic packaging machine, automatic cloth inspection machine, garment inspection machine and other automatic intelligent equipment, the enterprise productivity and efficiency has been further improved.